Japan Bets On Super Thin, Film-Like Panels to Reclaim Solar Leadership At Expo 2025

At Expo 2025 in Osaka, Japan is using an unexpected location—a bus terminal—to highlight its latest innovation: ultrathin “perovskite” solar panels, according to Nikkei.

More than 250 of these flexible, lightweight panels line the curved roof of the Yumeshima Transportation Terminal 1. Japan hopes this film-like solar tech will not only boost domestic renewable energy and reduce reliance on China, but also help it lead the next generation of solar innovation.

“It’s like killing three birds with one stone,” said Takayuki Taenaka of Japan’s Ministry of Economy, Trade and Industry (METI).

Photos: Nikkei Asia

Perovskite solar cells, discovered in 2009, are made from layers of chemicals just millimeters thick. Though still in early development, they rival traditional silicon-based panels in efficiency while being 20 times thinner and 10 times lighter, allowing installation on walls, rooftops, and even windows—places unsuitable for heavy panels.

“We believe this technology has the potential to beat the conventional silicon-based solar panels in terms of power generation efficiency,” said Futoshi Kamiwaki, president of Sekisui Solarfilm, which developed the panels showcased at the Expo.

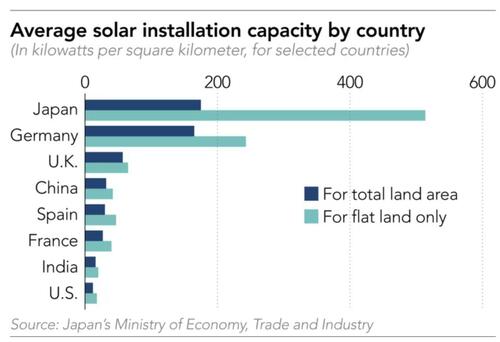

Japan, with limited flat land, leads major nations in solar capacity per km² but is running out of space. Installing perovskite cells on buildings could turn cities into vertical solar farms, helping Tokyo meet its 2040 goal: 29% of power from solar, up from under 10% today.

Sekisui plans to begin commercial shipments this year and start mass production by 2027. It’s investing ¥310 billion ($2.1 billion) in a new 1GW manufacturing facility—half subsidized by the government. A further ¥5 billion is allocated to help local governments adopt the tech.

Japan aims to generate 20GW from next-gen solar by 2040, equivalent to 20 nuclear reactors.

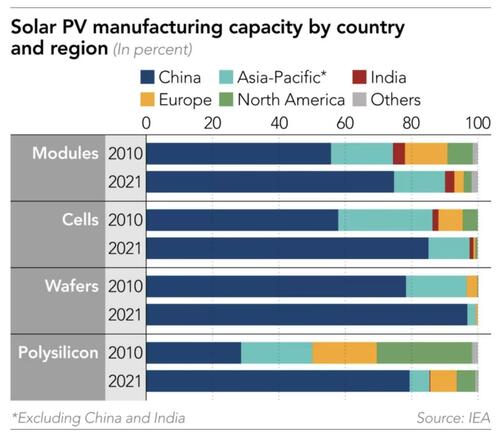

Japan once held a 50% global share in solar panels around 2000, but by 2023, that dropped to under 1%, largely due to China’s dominance. A METI report bluntly stated the government “lacked policies” to support industry growth and supply chains.

Today, China controls over 80% of all stages in the solar manufacturing process, thanks to its dominance in polysilicon.

“There is a risk in relying on one supplier,” said Taenaka. “The fact that the main ingredient for perovskite photovoltaic (PV) is iodine, which we are a major producer of, scratches an important itch for us.”

Nikkei writes that while Japanese firms focus on flexible perovskites, Chinese giants like Jinko Solar are developing tandem perovskite-silicon cells that reach up to 33.84% efficiency, compared to Sekisui’s 15% in practice and 30% in labs.

“It’s like cooking. Even if you have a frying pan and the right ingredients, the quality… depends on how good the chef is,” said Yukihiro Kaneko of Panasonic.

Analysts say Chinese manufacturers are sticking with tandem formats for now due to massive overcapacity in polysilicon production.

“The industry already struggles a lot from overcapacity… This transition to a different technology is not happening anytime soon,” said Yana Hryshko of Wood Mackenzie.

Still, Japan’s government is backing both film-type and tandem perovskites through its Green Innovation Fund, with subsidies expected as early as 2025.

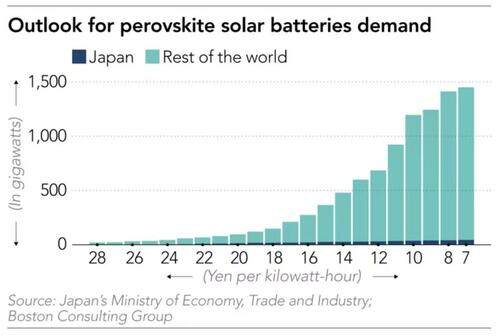

Despite the promise, cost remains the biggest barrier. Japan’s target is 10 yen per kilowatt-hour by 2040. But the global average for silicon panels is 5–6 yen, with China producing at just 2 yen.

“If the costs of perovskite panels can fall to the level of Chinese made polysilicon panels, then this Japanese technology can take off,” said Yasushi Ninomiya of the Institute of Energy Economics Japan.

BCG estimates that at 10 yen/kWh, global demand could reach 1,196 GW—nearly two-thirds of today’s total installed solar capacity.

But Japanese firms face a classic chicken-and-egg dilemma: no mass market without low prices, and no low prices without mass production.

“This is an industry that will need government support to at least 2030,” said Toshiba’s Tomohiro Tobari.

“What we want to avoid policy-wise is that due to a lack of demand and a market, mass production does not happen and costs do not come down,” said Taenaka.

“We are focusing on the domestic market now, but we’ll also need to look at how to sell this technology abroad,” he added. “Many people have now witnessed this technology at the Osaka Expo. The next step is to translate those eyeballs into actual business.”

Tyler Durden

Fri, 07/25/2025 – 18:50